Practical Training & Implementation for Office and Shopfloor

Hands-on training and guided implementation to create organised, safe and productive workplaces. Applicable to offices, stores, QC labs and shopfloor lines.

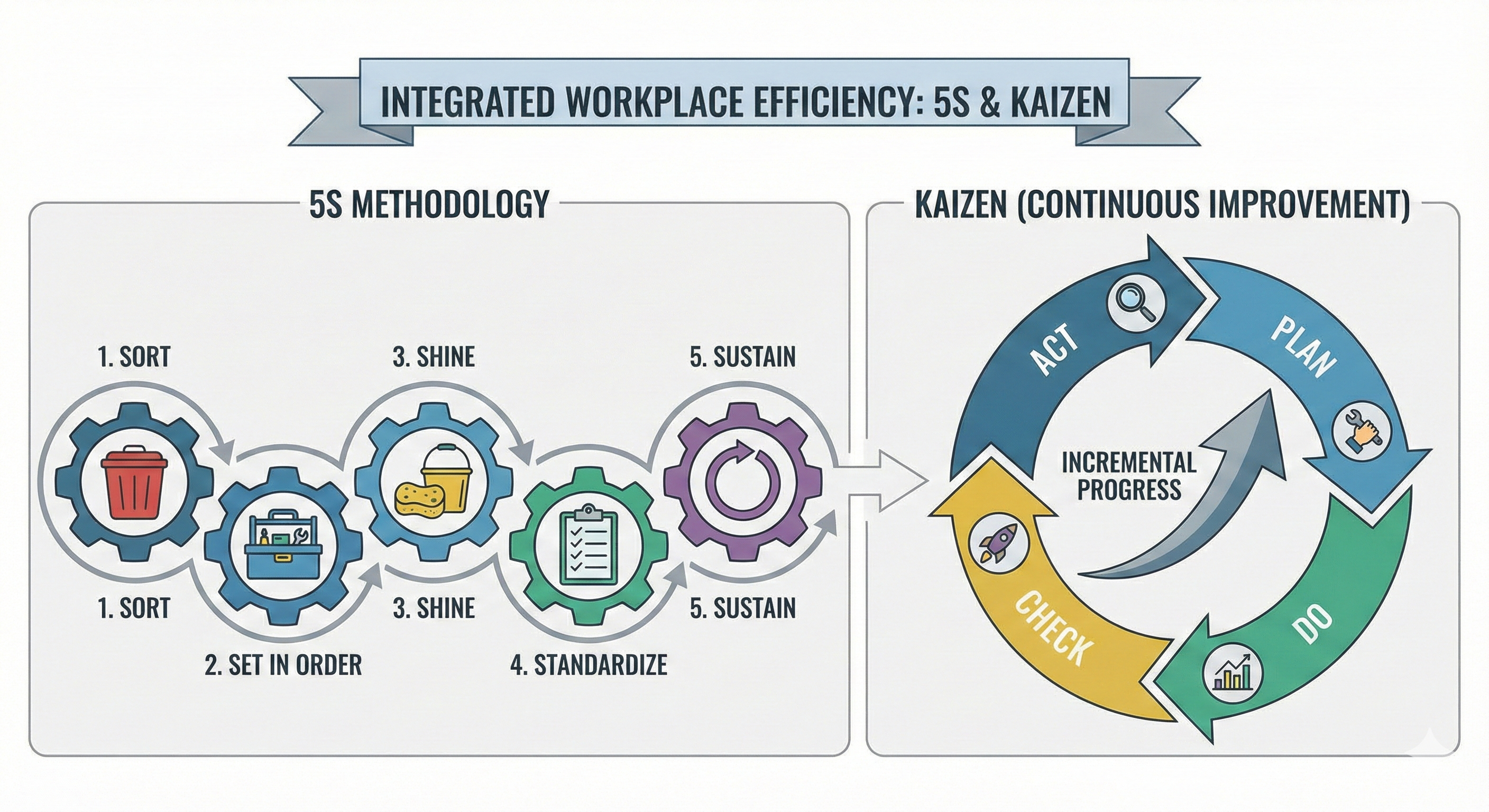

What is 5S & Kaizen Implementation?

5S and Kaizen are foundational Lean practices that improve workplace organisation, reduce waste, and build a culture of continuous improvement. Our services combine practical training with on-site implementation to ensure measurable and sustained benefits.

Scope of work

- 5S rollout (Sort, Set-in-order, Shine, Standardize, Sustain)

- Kaizen events and small improvement workshops

- Visual management: shadow boards, labels, floor markings, visual SOPs

- Checklists, audit formats and sustainment schedules

- Pilot implementation and follow-up audits

Deliverables

- Site-specific 5S Assessment Report (office & shopfloor)

- Prioritised action plan with effort & expected benefit

- Kaizen improvement register & ROI estimates

- Standardised checklists, SOP templates and visual aids

- Pilot implementation for selected areas and before/after documentation

- Training material, facilitator notes and audit schedule

Benefits

Office

- Organised document & record flow

- Reduced search time for files and stationery

- Standardised desk and meeting-room practices

Shopfloor

- Quick access to tools and spares (shadow boards)

- Reduced downtime and fewer quality issues

- Improved safety and machine area discipline

Example use-cases

- Tool shadow board & tool control implementation

- Stores re-layout with 5S and FIFO markings

- QC lab 5S & documentation controls

- Kaizen event to reduce defect rate or process cycle time

- Office records 5S and digital indexing

Training Programs — 5S & Kaizen

Structured training options designed for different audiences and outcomes. Each program includes practical exercises, templates and post-training support where applicable.

5S Awareness (Office + Shopfloor)

Duration: 2–3 hours

- Introduction to 5S principles and benefits

- Examples and common pitfalls

- Interactive red-tagging exercise (simple simulation)

- Pre/post quiz and quick action list

5S Implementation (Hands-on Workshop)

Duration: 1 day (on-site)

- Conduct a practical 5S audit of selected area

- Sort & red-tagging, Set-in-order layout planning

- Visual management, labels, shadow boards

- Create checklists, owner matrix and sustainment plan

- Pilot implementation on 1–2 zones

Kaizen Workshop — Problem Solving & Small Improvements

Duration: half day / full day

- Identify wastes and bottlenecks using practical tools

- Techniques: 5 Whys, Fishbone, Waste Walk

- Team-based improvement and rapid experiments

- Action register, prioritisation and quick ROI estimate

Train-the-Trainer (TTT) — Build Internal Capability

Duration: 2 days

- Facilitation skills and running audits

- How to lead Kaizen events and sustain 5S

- Templates, slide decks and audit packs for internal use

- Certification for internal champions

Training Deliverables

- Training slides and participant handouts

- 5S checklists, red-tag templates and audit formats

- Kaizen action register template and example reports

- Participant certificates (optional)

Enquiry / Request a Workshop

Fill details and click Submit & Send WhatsApp to send a request (keyword: 5S-KAIZEN) and save your enquiry to our sheet.

Pilot recommended

We usually run a 1–2 area pilot to demonstrate value, then roll out in phases for sustainment.

Why choose us?

Practical, low-overhead solutions focused on shopfloor realities and office workflows — with clear sustainment plans and internal capability building.